Forged Flange Manufacturer

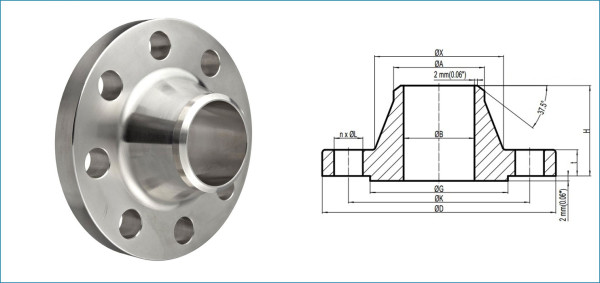

Zizi is engaged in manufacturing and delivering top class Stainless Steel WN Flange which is tested for durability and stability by our supervisors. The usage is well defined and widely used accordingly. They are most suitable for the demanding occasions, such as pipe system with large pressure or temperature fluctuation, or with high temperature and pressure. Also very useful in transferring medium which is expensive, flammable and explosive.

Stainless Steel WN Flange Dimensions

| Diameter | NPS1/2-NPS24/ DN15-DN600 |

|---|---|

| Pressure | Class 150, 300, 600, 900, 1500, 2500. PN6, PN10, PN16, PN25, PN40, PN63, PN100 |

| Seal | Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ), Tongue-and-Groove (T&G) |

| Material | ASTM A182 F304, F316, F310S, F321, F317 |

Weld Neck Flange Standard

- ASME B16.5

B16.5 standard covers specification from NPS 1/2 to NPS 24, pressure class 150 to class 2500. Also specified the materials, tolerances, marking, testing, and methods of designating openings.

- ASME B16.47

B16.47 standard are large diameter which from NPS 26 to NPS 60 metric/inch. The pressure ratings are class 75 through class 900, but most forged flanges at least are Class 150.

- BS4504

BS4504 is now obsolete and replaced by EN1092-1edition 09-2008, but people still call them BS4504 Flanges. Those flanges are from DN10 to DN2000, pressure is in PN6 to PN100.

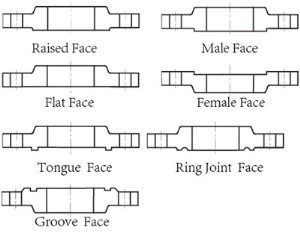

Stainless Steel Industrial Flanges Seal Types

RF Flanges are the most common type used in process plant applications. Their gasket surfaces are raised above the bolting circle face.

- Flat Face

FF Flanges have a gasket surface in the same plane as the bolting circle face. Applications using flanges which are made from a casting.

- Ring Type Joint

RTJ Flanges are typically used in high pressure (Class 600 or higher ) and high temperature services above 800°F (427°C). They have grooves cut into their faces.

Stainless Steel Forged Fittings and Flanges

Both forged fittings and flanges are belong to forging with material ASTM A182. The most common used are F304 and F316 which have good performance and long service life.

And some Duplex Stainless Steel WN Flange are very resistant to hydrogen corrosion with good weldability. They can satisfy your most demanding requirements. The most material grades are ASTM A182 F51, F53 and F57.

Stainless Steel 304 Chemical Properties

| C | Mn | P | S | Si | Ni | Cr |

|---|---|---|---|---|---|---|

| 0.08 | 2.0 | 0.045 | 0.03 | 1.0 | 8-11 | 18-20 |

Stainless Steel 316 Chemical Properties

| C | Mn | P | S | Si | Ni | Cr | Mo |

|---|---|---|---|---|---|---|---|

| 0.08 | 2.0 | 0.045 | 0.03 | 1.0 | 10-14 | 16-18 | 2-3 |

Latest News

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...  29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...

29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...  19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....

19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....